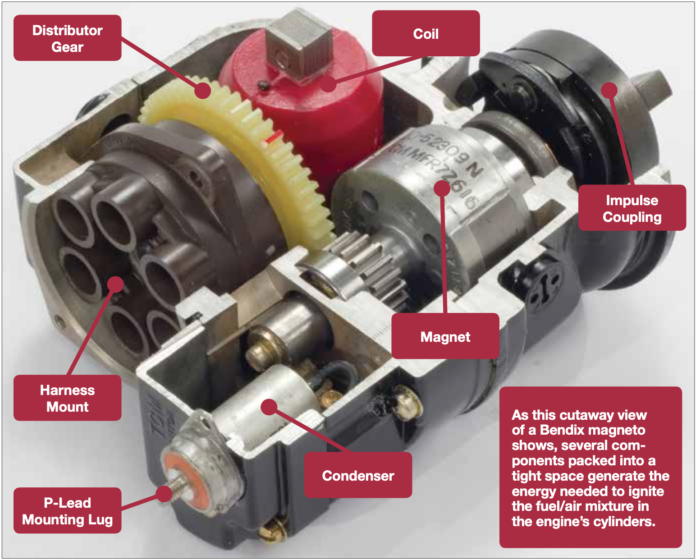

Unless you’re lucky enough to fly a turbine or an engine with an electronic ignition system, the internal combustion engines you fly behind or between likely operate using a simple system involving a magnet, coil, condenser and contact points. As the spinny thing in the accessory case turns the magneto drive shaft, the magnet rotates and imparts electrical energy to the coil. When the points close, a jolt of electricity is sent from the coil to the respective spark plug wire to the attached spark plug and, kaboom, the cylinder fires. At least that’s the way it’s supposed to work.

Meanwhile, a second magneto does the same thing, preferably at the same time, to a second spark plug in the same cylinder. Between two magnetos and two spark plugs operating in sync, the engine will deliver power with a bit more efficiency than a conventional engine with only one spark plug per cylinder, everything else being equal. There’s also a so-called “dual” magneto, which uses only one drive shaft but fits two ignition harnesses. The design can simplify installation and maintenance but at the expense of some redundancy. And redundancy is always good.

The trusty magneto has been with us pretty much as long as internal combustion engines have been around, and the basic technology hasn’t change much in a century or so. With magnetos, spark-ignition engines don’t need an aircraft electrical system. Instead, they generate the electrical energy needed for ignition as long as they’re within specification and correctly synchronized (timed) internally and to the engine. They’re typically painted black and are mounted to the accessory case at the top rear of the engine. They should be easy to identify; they’re the accessories with the ignition harness wires leading off to the spark plugs.

Magnetos are a relatively simple electro-mechanical system, but they are subject to wear and tear, plus the stress of creating and releasing thousands of volts each minute. The nice thing about having a pair of magnetos is that one can fail and the engine still runs, just not quite as well. I know this because I have had the experience of a magneto failure, which ended with a safe landing at my home airport.

A major part of the pre-takeoff checklist in aircraft equipped with a typical spark-ignition engine is the magneto check. The checklist and/or the aircraft’s documentation will specify the maximum allowable rpm drop on one magneto and the maximum difference between the two. If the mags pass the check, we go fly. What if they don’t pass, or if there’s no rpm drop on one or both mags?

Excessive RPM drop

An rpm drop exceeding specifications may be accompanied by a rough-running engine. If so, it’s possible one or more spark plugs are fouled with lead or even engine oil, and “burning off” the contamination may fix the problem. To do so, place the mag switch back on the offending mag and carefully lean the mixture. You should see the rpm rise slightly as you lean. When it peaks, stop leaning and let the engine run with that mixture setting for a few seconds. If the roughness disappears, congratulations, you’ve successfully burned off the fouled plug. Return the mixture control to its preferred setting and perform the complete mag check again. If the roughness doesn’t disappear, the test has failed and the aircraft isn’t airworthy. Contact a mechanic for evaluation and/or repairs, which may be as simple as replacing a bad spark plug.

No rpm drop

If there’s no rpm drop on one or both magnetos, something’s wrong. Either the magneto switch is faulty or the offending magneto’s P-lead isn’t grounding it correctly. Either case means the aircraft isn’t airworthy and repairs are needed, which could be as simple as replacing the P-lead.

In-flight/Shutdown checks

Magneto tests aren’t limited to before-takeoff checklists. Performing them in-flight, but not at full power, is certainly allowable, especially if you become concerned about a mag or spark plug. Back on the ground and before shutdown, checking the mags at low rpm is a good post-flight measure. —J.B.

SIMPLE AND SOMETIMES FICKLE

Magnetos are mechanically driven by the engine, so there are bearings and couplings to worry about. For the electrical energy to jump from the coil to the spark plug wire, two pieces of metal—the contact points—have to make contact as the shaft rotates to convey the electricity. More opportunities for wear. The failure of the spark to make it across the contact points might be due to a bad capacitor, one with an open- or short-circuit failure. Due to age, the coil also may not be delivering adequate voltage. Worn contact points is another failure mode, perhaps due to arcing, which can result from the capacitor or coil being out of spec.

The beauty of a magneto is its simplicity. When one fails, it’s not dramatic, and will not result in a catastrophic engine failure unless both mags shoot craps at the same time. If that happens, the engine will stop running or might run rough (missing on one or more cylinders). Losing a magneto will not cause the engine to blow up or send a valve through the engine or blow a cylinder head. The engine just won’t make as much power. If you’re lucky, you may not even notice the failure until the next mag check.

That said, the problem with magneto failure you will only have one system igniting the spark. With a failed magneto, you will make slightly less power, but you are now 100-percent dependent on the single remaining magneto in the system, one that just demonstrated to you that it isn’t always reliable.

A logical person would consider the fact that chances are both magnetos were put on the plane at the same time. They very likely even share a common history of either being from the same manufacturer or rebuild shop, and were installed by the same mechanic. Their common heritage makes it prudent to complete the flight or return to base, and to be mindful of alternative off-airport landing options along the way.

Once one magneto fails in flight, it behooves you to keep altitude to maximize potential gliding distance. Also keep your power setting changes to a minimum (engine failures occur most often during major power changes). If your engine is humming along on the remaining mag, leave it alone. When making power changes for approach and landing, make them smoothly and slowly.

When my left magneto failed recently, my mechanic back home had a spare on the shelf, kept for a pilot who frequently flew to Alaska. On those long hauls, a spare magneto provided insurance that he wouldn’t be stuck on the ground at some remote location waiting for the next shipment of parts to arrive. You may still need someone to install it, however.

DECLARE AN EMERGENCY?

When a magneto fails, should you declare an emergency? Probably. If the other magneto goes out, you will wish you had. If you are in busy airspace, controllers will give you priority handling and, if there are numerous planes in the pattern at your intended airport, they will yield their spot in the pattern to you, as they should. Anything that helps you beat the odds and land safely should be used to your advantage. That’s what the E-word was invented for.

Should you perform a precautionary off-field landing? I wouldn’t, unless in addition to the magneto failure you also have a rough engine. With a single failed mag, chances are the engine is still running strong, just not as efficiently. If it is very rough on the remaining mag, a precautionary landing at the nearest airport makes a lot of sense. If it is running smoothly, but on only one mag, I personally would cautiously proceed to my destination airport as long as it’s not hours away.

ALWAYS CHECK MAGS?

I always check my mags, but not always on the ground. When operating on gravel and dirt strips, a high-rpm runup can cause unwanted damage to the aircraft, including the prop and tail. Once in the air, you can verify the mags are both working. This should not be done in a climb or while developing full power, but rather at a reduced power setting that results in less engine strain.

There are exceptions. I heard a case where the mag failure was due to a gear in the accessory case failing. The mag check is what presented the failure, which resulted in metal components in the interior of the engine dropping to the bottom where they would be chewed up. Had the pilot proceeded to fly after the failed mag check, the engine would have likely suffered a catastrophic failure due to the accessory case internals bouncing around. Fortunately, the failed mag check resulted in an immediate grounding of the plane and disaster was averted. In this case, the failed mag check wasn’t actually due to the failure of the magneto itself, but rather the internal components deeper in the engine that turned the magnetos.

P-LEADS AND HOT MAGS

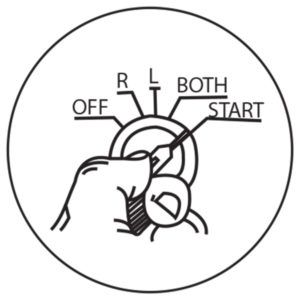

When magnetos are switched to the “Off” position, the P-leads to the magneto’s primary coil are grounded. A magneto with a grounded P-lead will not operate. If the P-lead is not grounded, either by switching them on or by a failure of a P-lead, the engine has a “hot” mag, one that can and will discharge its electrical energy if it is rotated so that the points close. This means the engine may start, even if the keys are in your pocket. See the sidebar above for a tragic example.

I own a Piper J-3 Cub with no electrical system. The only way to start the engine is to hand-prop the airplane, an experience that has taught me one thing: A prop is a hair-triggered son of a bitch ready to kill you. While I have occasionally winded myself trying to start persnickety engine, I have learned to not flood the carburetor and figured out the secret sauce it takes to make the engine turn over.

Cued with the right stoichiometry, a single spark will bring the engine to life with the lightest, most innocuous turn of the prop. If the prop is in the right position and the impulse coupling is ready to click, a few ounces of pressure or a few millimeters of motion can be enough to send electrical energy through the ignition harness to a spark plug, and that can be more than enough to start the engine.

To avoid accidental hot props, it is a good idea to do a mag check at the end of each flight. Slowly rotate the key from left, to right, to the “Off” position to verify whether “Off” is truly “Off.”

“After completing a personal flight with his wife, the private pilot secured the engine by placing the mixture control in the idle cut-off position. Based on physical evidence observed after the accident, he likely moved the ignition switch toward the off position and removed the key. The pilot’s wife indicated that, after they performed local errands and returned to the airport, the pilot was performing his preflight inspection of the airplane with the ignition key in his pocket. Although airport security video did not capture the accident sequence and the pilot’s wife, who was by the airplane’s right cabin door, did not see her husband move the propeller, she heard the propeller move and the engine starting or trying to start. The pilot likely slightly moved the propeller and the engine briefly started; the propeller then rotated and fatally injured the pilot. The engine did not sustain operation, and the propeller ceased rotating.”

This accident resulted from a worn ignition switch that allowed the key to be removed without being in the “Off” position; at least one magneto was not grounded. Even though the throttle was at a low-power position and the mixture at idle cutoff, slight movement of the prop allowed the engine to achieve enough power to deliver a fatal blow.

(Editor’s Note: The deceased pilot was a neighbor of mine. I didn’t know him well, but we spoke to each other on the CTAF a few weeks before this accident. —J.B.)

Two comments;

– the points are normally closed. When the rotor induces the maximum current in the primary coil, the points open , which causes the magnetic field to collapse rapidly, inducing the high voltage in the secondary coil, which fires the plugs.

– broken teeth on the distributor gear can cause the mag to fire the wrong plug, which will cause rough running. Switching to each mag will identify the ‘bad’ mag, and the good mag will run the engine ok.

In September Jeb put out a great article about pre-flighting propellers and I added this comment to that article but since we’re talking about mags and the potential to get killed moving a prop, I’d like to re-post my comment in hopes it might prevent a tragedy. (Note: Could someone who knows exactly how mags work verify that they WON’T fire if rotated backwards.)

There is a safe way to move a prop. In Alaska I was taught by a bush pilot who always had to “hand” prop his engine to start that you NEVER touch the prop with your hand. EVER! (He also used some strong words in front of “ever” to make his point). He carried about a three foot loop of rope he showed can be looped over the prop so you can stand a safe distance from the prop (with all body parts out of the arc) and rotate the prop. If the prop hits the rope, no big deal. If you forget the rope, you can always use your belt. You can use anything except what is connected to your body. And if you need to move the prop in order to inspect it or to push the plane, use your rope (check to make sure the keys are out but still don’t trust the switch) and rotate the prop in the opposite direction. The mags are not designed to fire going backwards. DON’T EVER (he used a strong word again) rotate a prop going forward unless you are trying to start the engine. I’ve never had to hand prop a plane. But his words ring in my ears every time I’m around a prop. I sincerely believe if every pilot handled a prop with their “Alaska starter” rope or something similar, there would be fewer maimings and deaths from prop accidents.

The impulse coupling inside the magneto will not operate if the prop is rotated opposite to normal rotation, so no spark is generated.

“An rpm drop exceeding specifications may be accompanied by a rough-running engine. If so, it’s possible one or more spark plugs are fouled with lead or even engine oil, and “burning off” the contamination may fix the problem. To do so, place the mag switch back on the offending mag and carefully lean the mixture. You should see the rpm rise slightly as you lean. When it peaks, stop leaning and let the engine run with that mixture setting for a few seconds.“

You’ve got to be kidding me. How are you going to burn off deposits if you don’t have a good fire? You go to “both” to clear a fouled plug, rather than just running on the bad mag. You need fire to burn the deposit off, that fire is provided by the spark plug that isn’t fouled.

Good that readers are noticing errors in this article. Too bad some articles these days are written by folks that don’t know enough, and also that they don’t bother correcting errors. Should have included an explanation of impulse couplings, overhaul recommendations, and the various magneto configurations that have evolved over the years.

I agree with the previous comments, this article leaves could have been much better. The picture is way more helpful than the article itself.

“As the spinny thing in the accessory case turns the magneto drive shaft, the magnet rotates and imparts electrical energy to the coil. When the points close, a jolt of electricity is sent from the coil to the respective spark” Which is the “magneto drive shaft”, is it shown in the picture? What “points close”? How is the electricity sent from the coil, is there a wire from the shaft? What does the induction coupling do?

magneto 6210 , pode ser instalado no motor O-540-